©2004-2019 Philip Bergstedt. All photographs appearing on this site are the property of Philip Bergstedt (except noted). They are protected by U.S. Copyright Laws, and are not to be reproduced without the permission of Philip Bergstedt. All Rights Reserved.

Amp Case Building Project

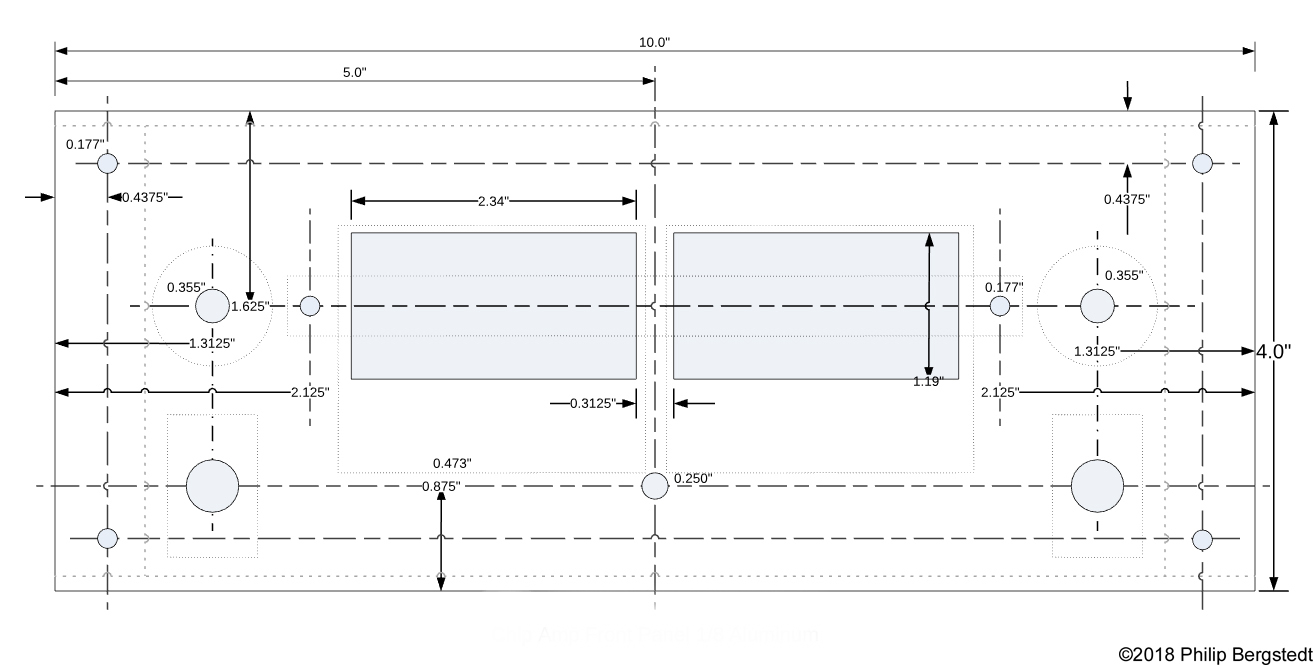

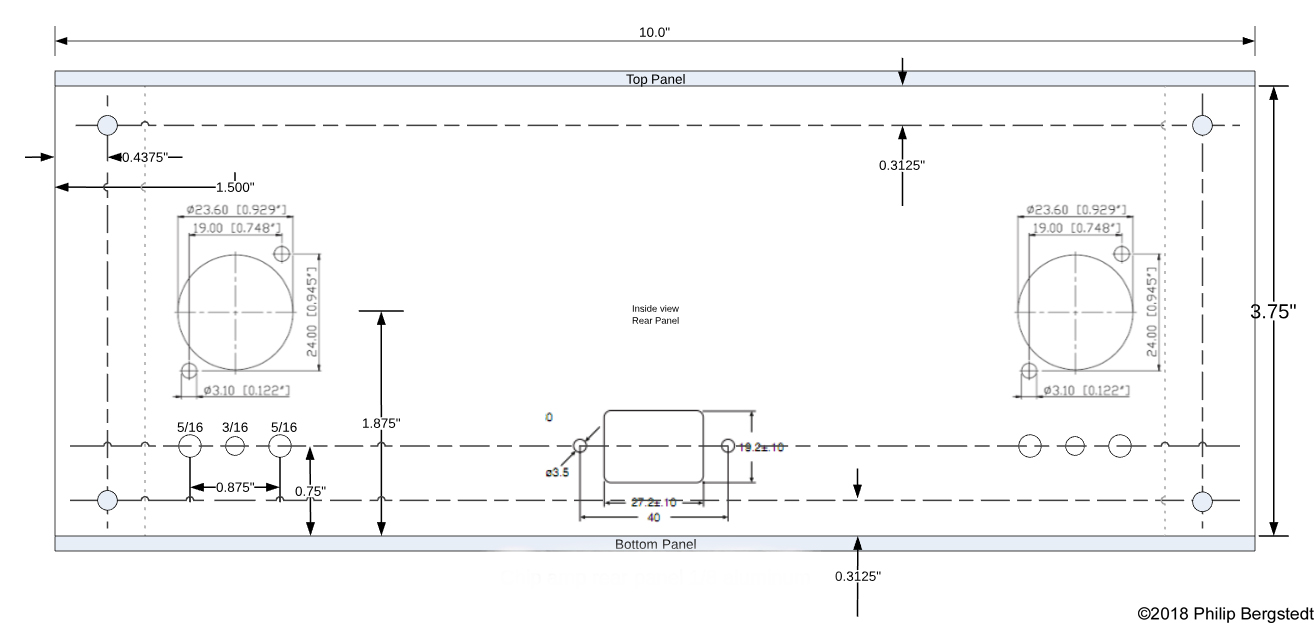

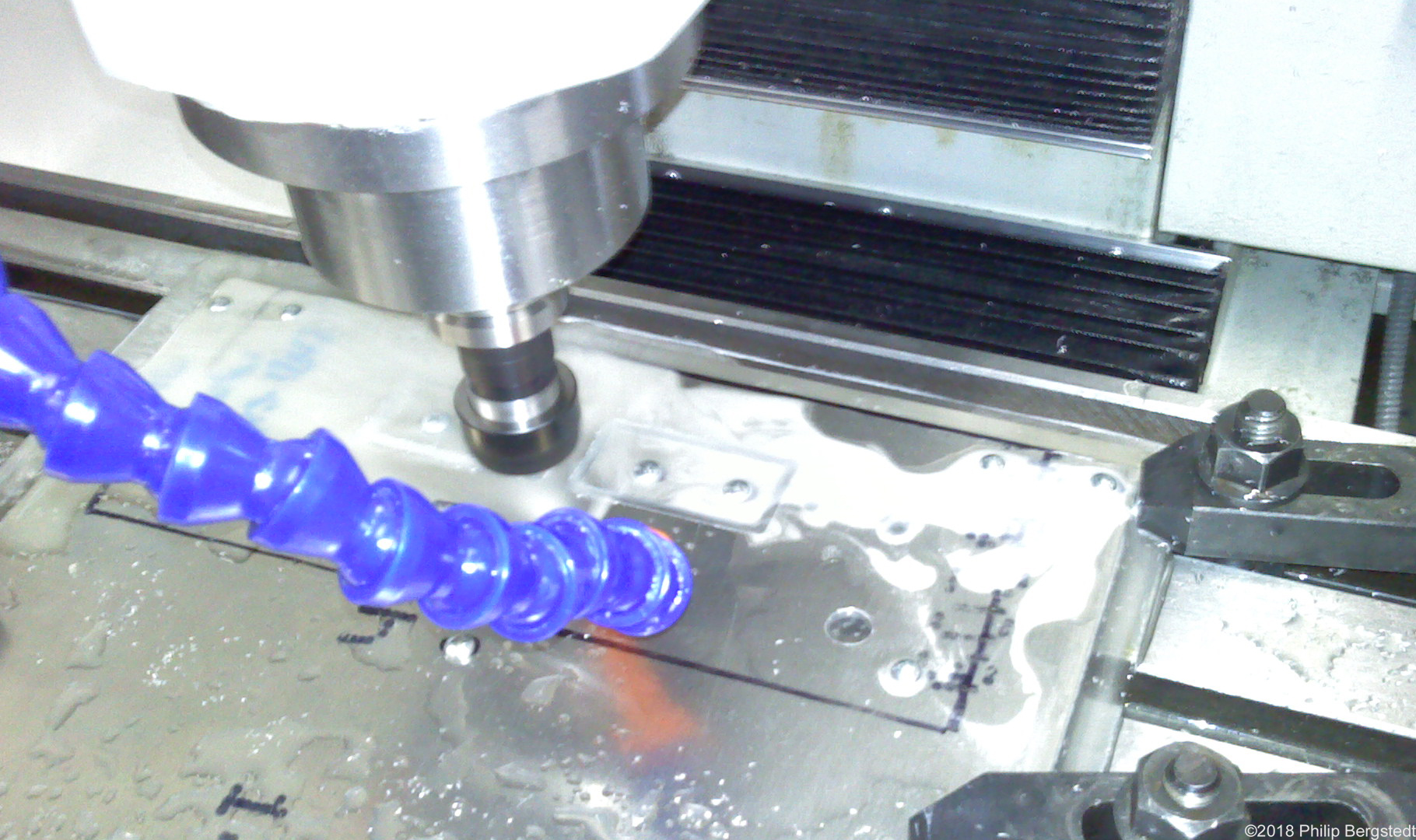

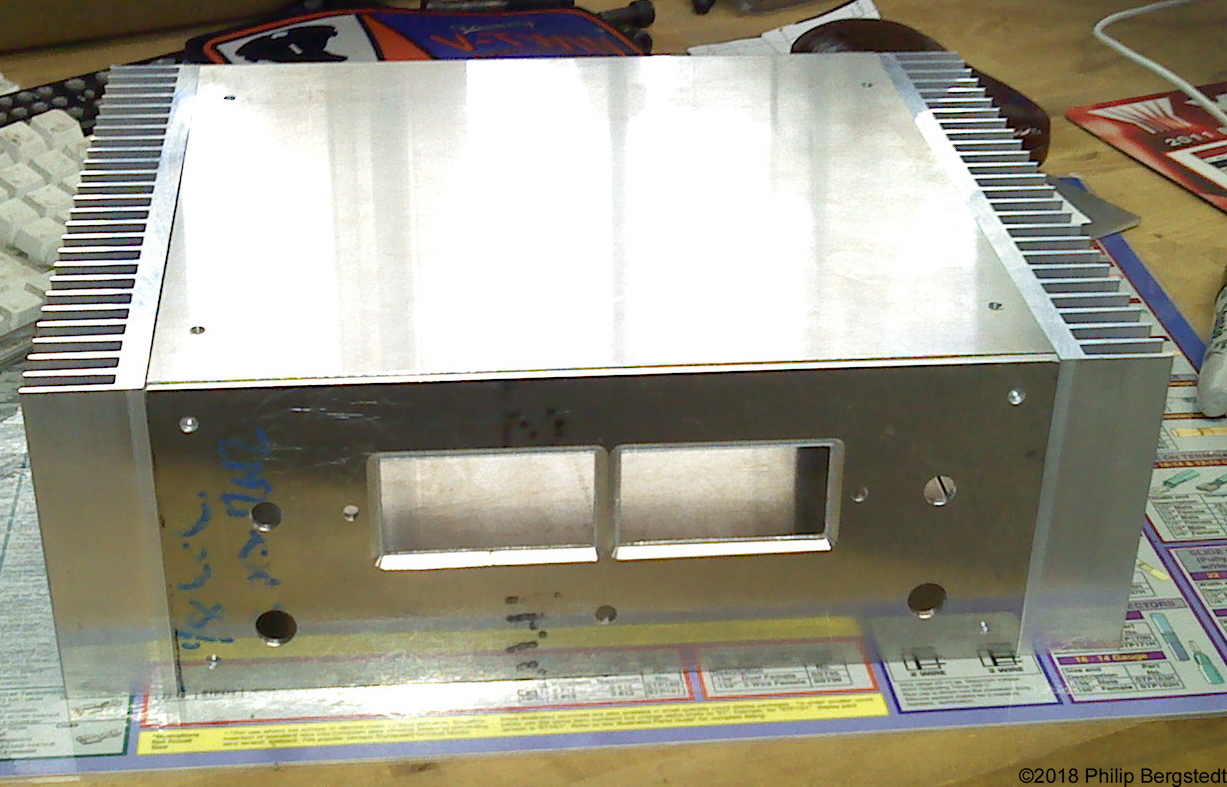

Building a case was a lot of fun, and it really helps when you have a good friend that owns a CNC machine. I used 1/8 inch Aluminum for the front, back, bottom and top. The sides are all heatsink, and I ordered them from HeatsinkUSA. The first step was to CAD out the design, I wanted to have power meters (for no other reason than they look cool) and holes for speaker, power and volume controls. The rear panel is simple, power plug, speaker and input. I wanted the case to be big enough to reuse on other projects and be easy enough to wire and hold whatever transformer config I come up with. I’m very happy with the way it came out.

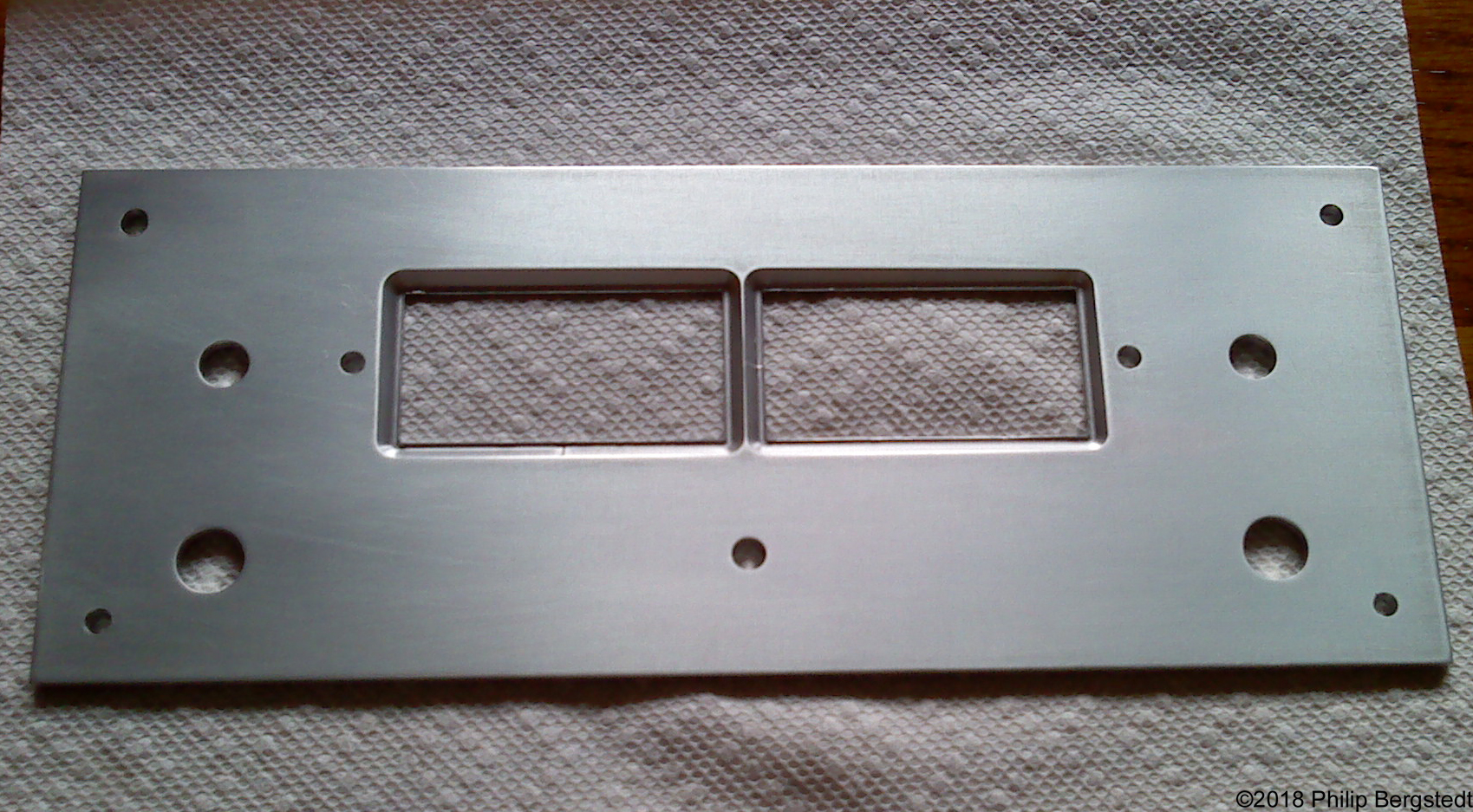

Case CAD drawing front panel

I had never anodized aluminum (picture below), that was a new experience, but it really works and keeps the panels looking new. I used a 12V car battery charger as my power source.

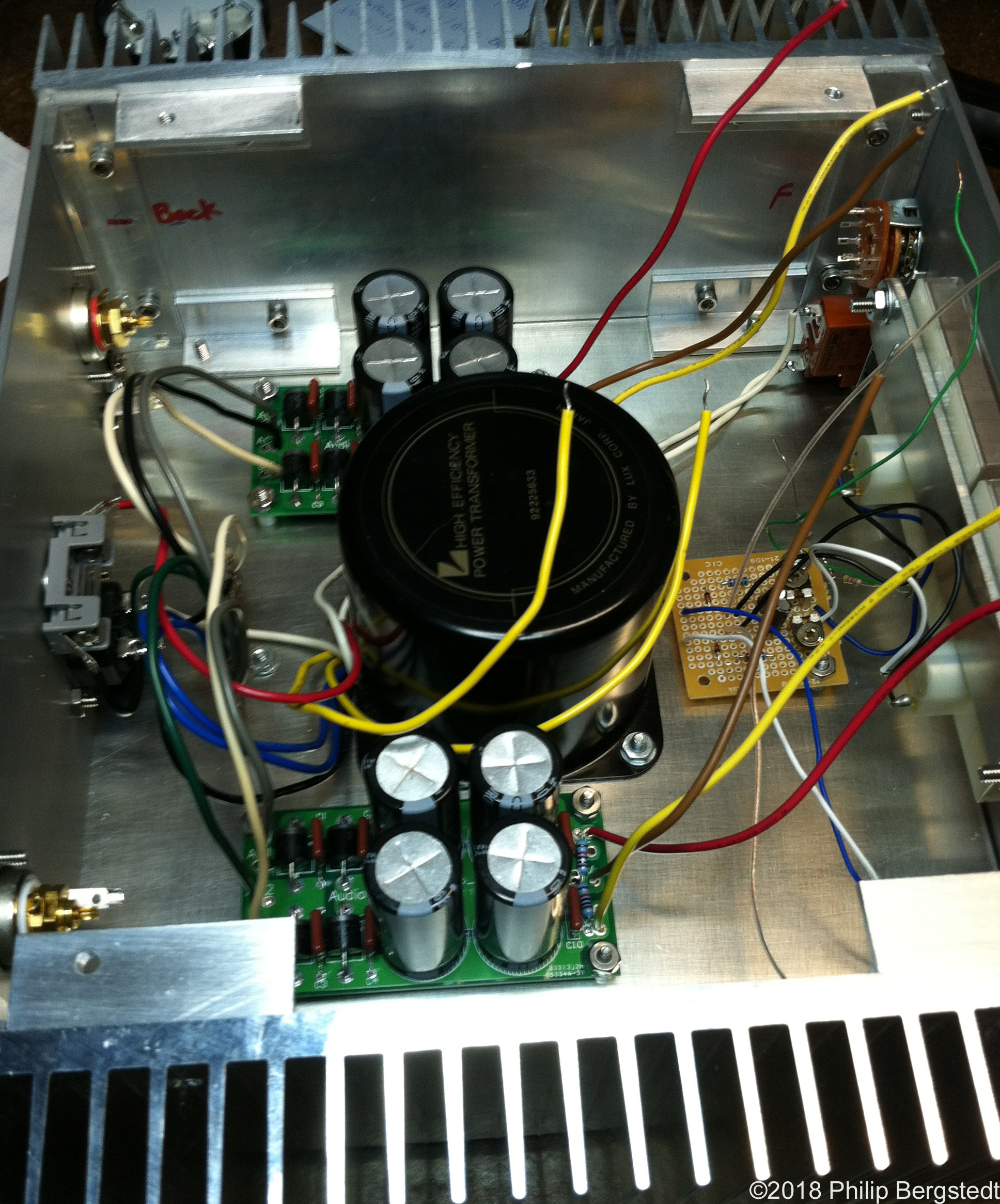

First assemblyThe first project I used the case for was my LM3886 chip amp (yes I know I state on the home page discrete design and build, but I had read so much about the LM3886, I had to build one myself). The case was overkill for this project, but it allowed me to utilize my new build and design. They say there is no such thing as too much heatsink, but for this build, with the entire case participating in heat dissipation, the chips never get close to being hot.

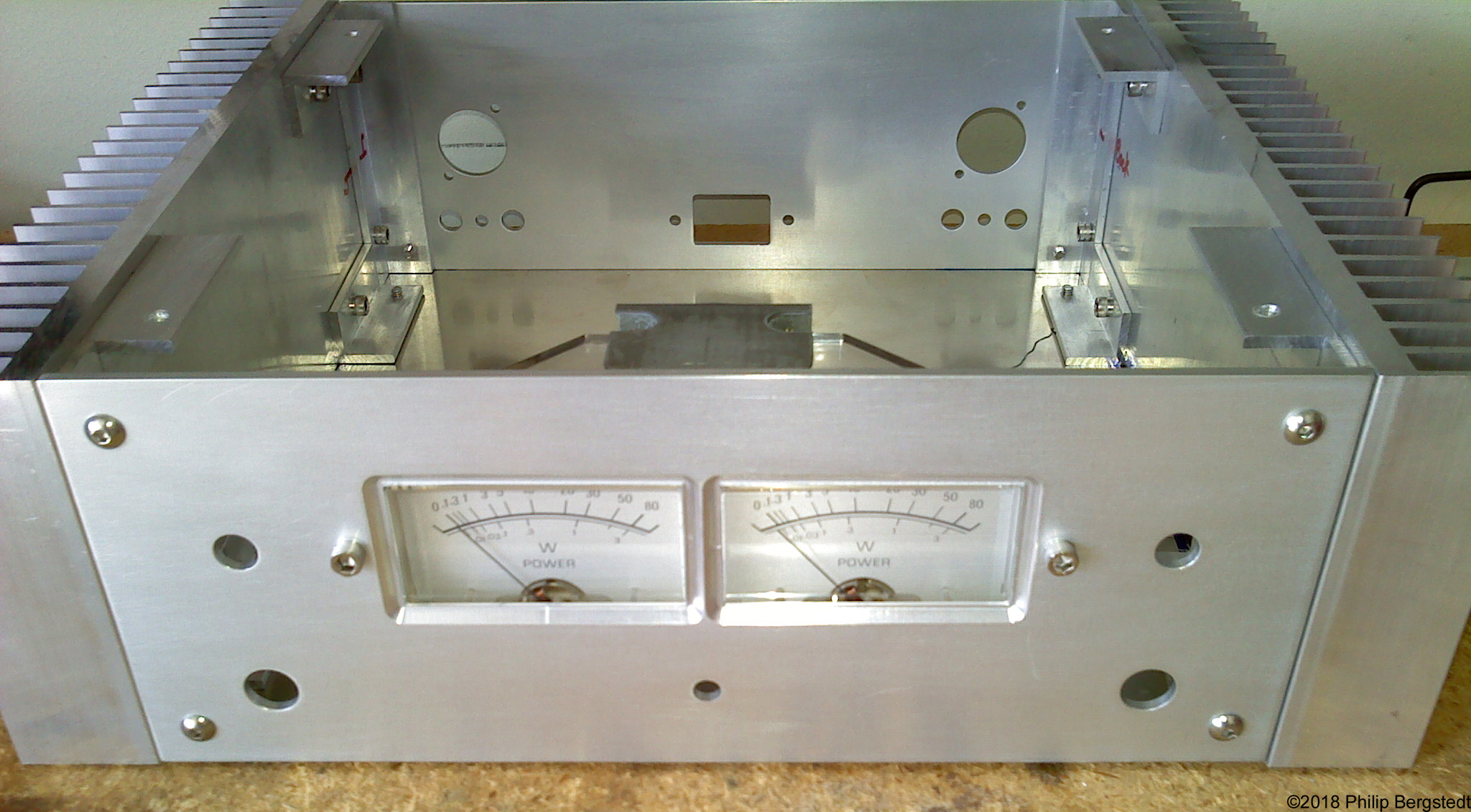

Assembly with power meeters installed